Maintaing the gateway to the world

Heathrow Airport is one of the busiest airports in the world and as London’s main airport, it is home to 86 international airlines serving over 180 destination in 90 countries, with more than 1300 daily aircraft movements and between 100,000 and 200,000 passengers moving throughg it's terminals every day.

Heathrow Airport Limited (HAL) being as one the UK’s most significant construction industry clients, continually invest in the construction, refurbishment and repair of its infrastructure. Among its current major projects is the refurbishment of the short stay multi-storey car park in terminal 4, which was officially opened by His Royal Highness Prince Charles and Princess Diana on 1st April 1986.

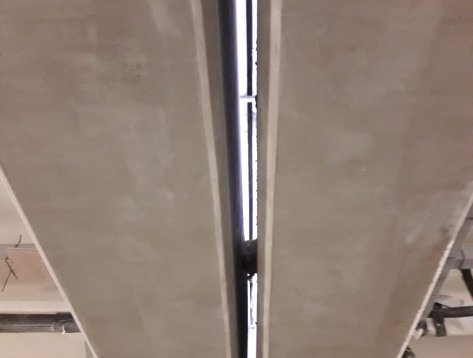

The MSCP at Terminal 4 was built in 1986. It consists of a concrete frame structure with insitu concrete decks. Over the years the concrete decks and beams have started to deteriorate, mainly due to corrosion of the reinforcement. This is caused by the vehicles tracking chlorides (from road salts) into the car park which then permeate into the concrete and initiating the corrosion process.

Whem HAL realised they had a problem, a tender was issued and CRL were successful in securing phases 1 & 2. CRL have now been working on Heathrow T4 Car Park for over three years and have just completed Phase 3 of the concrete repair and strengthening works on the car park.

The scope of the works was mainly concrete repairs to the cross beam and columns of the car park. This includes propping, removal of the defective concrete by high pressure water jetting, grit blasting of the exposed reinforcement, placing formwork and re-instating the defective concrete using a Weber product. Other works carried out include the removal and reinstallation of movement joints within the car park.

Working on one of the busiest airports in the world UK, alongside the public and ensuring the car park remained in operation has provided many challenges and required to CRL to work to extremely high standards. HAL has always insisted on a high level of quality and service. This has neccesitated CRL working closely with the client representative, resulting in us completing Phase 3 snag free and to the high standard required within the industry.

CRL is confident that with the experience gained we are now able to move forward with HAL to carry out future projects with confidence.

The works consisted of the following;

-

- Installation of temporary propping,

- Removal of the defective concrete by high pressure water jetting,

- Installation of formwork,

- Concrete repair,

- Concrete compressive strength test,

- Removal of existing movement joints,

- Installation of new movement joints, and

- Application of anti-carbonation paint.

"Working on an operational car park in close proximity to the general public was a real challenge, but with good collaboration between all the stakeholders involved we proved that the works could be carried out safely."

Khalid Rahmany | Project Manager | CRL