CRL Delivers on 60-Year Old Motorway Bridge Refurbishment Project

Innovative thinking, and collaboration with the client and stakeholders, allowed major concrete repair works to be undertaken and a lengthy abnormal loads restriction to be lifted several months early on the River Dane Bridge in Cheshire.

The project, a £6m structures upgrade project on the River Dane Bridge - an 85-metre long viaduct which was originally constructed in 1962 and carries the M6 motorway over the River Dane between junctions 18 and 19 near Holmes Chapel in Cheshire, was carried out on behalf of National Highways..

The bridge consists of a five span simply supported beam and slab structure with a longitudinal joint in the centre and with separate substructures on either side of that joint. Each superstructure consists of 23 precast prestressed concrete ‘I’ beams and a precast reinforced concrete edge beam. (See Image CRL005-1)

During routine inspections it was observed that de-icing salts had migrated through the bridge joints to the underlying crosshead beams, piers, and columns, and penetrated through the concrete cover causing the reinforcing to corrode. This had resulted in large areas of concrete spalling which was detrimental to the long-term structural integrity of the bridge.

National Highways commissioned the repair works as part of its commitment to maintenance improvements to motorways and major A roads in the North West area.

A significant challenge for CRL on this project was ensuring that the bridge remained open to vehicular traffic during the works and that the project was completed on time. Tens of thousands of road users travel on this busy stretch of the M6 daily, so keeping the structure operational was crucial to ensure minimal disruption to the travelling public.

After a lengthy 18 month early contractor involvement (ECI) and negotiation process, CRL was selected as the Principal Contractor for the project and worked closely with National Highways to design and develop plans for the major repair works. Once the works were completed, the bridge would comply with current standards, have a minimum design life of 50 years, and again be able to carry abnormal loads. CRL first commenced work on the bridge in February 2022, utilising a three phase programme which allowed the works to be carried out in a controlled manner. The third and final repair phase is due to finish in April 2024.

Since April 2022, the load carrying capacity of the bridge was reduced to a maximum of 80-tonne heavy load vehicles, with this reduction due to remain in place until April 2024. However, this had a long-term knock-on effect for hauliers and companies transporting heavy goods, as trucks had to be rerouted along a lengthy diversion. However, thanks to close collaboration and the efforts of CRL and National Highways, the bridges weight restrictions were lifted in October 2023, several months ahead of schedule.

The innovative nature of the scheme has already been recognised, with it receiving the coveted ‘Project of the Year’ title at the National Concrete Repair Association (CRA) Awards hosted in Liverpool in October 2023, as well as the CRA ‘Repair & Refurbishment Award’ presented at the Concrete Society Awards in London in November 2023.

The works across the three project phases has involved surveying and testing of the structure, removal of all delaminated, sub-standard, and sub-strength concrete and preparation of the repair areas by hydro-demolition, cleaning of the steel reinforcement and repairing/replacing where necessary, followed by the reinstatement of the broken out areas using Weber’s Webercem Advanced Precision Grout. An Impressed Current Cathodic Protection (ICCP) system consisting of a mesh and overlay arrangement was then installed to the crossheads and columns to protect the reinforcement in the structure and provide further corrosion prevention measures.

River Dane Bridge had been subject to previous surveys and repairs over the years, and although the earlier repairs had performed well, it was decided that the installation of a cathodic protection system was now necessary to minimise future corrosion of the reinforcing, and any subsequent spalling. Not only would the system save costs, but by not having to return to the bridge to carry out future repairs, there would be no need to restrict the movement of large vehicles over the bridge.

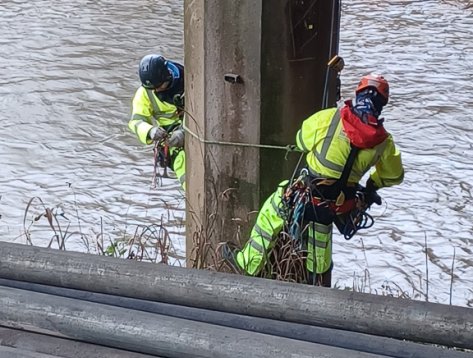

As can be deduced from its name, the River Dane Bridge carries the M6 motorway over a river, and in order to carry out the works safely, a complex bes poke temporary works system was produced for the scheme. This

consisted of steel buckling straps and scaffold support steelwork, with the buckling straps clamped around the columns at the top and bottom of the repair areas. This maintained the stability of the existing structure and removed the risk of the reinforcement collapsing when the concrete was removed via hydro-demolition.

The scaffold support steelwork comprised steel brackets which were drilled and fixed onto the columns. A steelwork frame was then bolted onto them, thus taking the weight of the access scaffold above. This removed the need for any excavation works within the river or the motorway embankment, which would otherwise have been necessary to establish foundations for a conventional scaffold/access system. This system also had the added advantage of raising the height of the scaffold above the river water level, which avoided any potential damage during a flood event.

Environmental responsibility was a key focus throughout the project. Working on a major motorway over a river for a sustained period of time brought about several environmental challenges. Close liaison was needed with the landowner, the Environment Agency and the local fishing club to ensure that the project was undertaken and completed without any negative impact to the river and local wildlife. In order to ensure no contamination of the surrounding land, or the river occurred, full water containment was implemented and monitored whilst hydrodemolition was being carried out. The collected water was then passed through a PH adjustment system which reduced the PH to a suitable level whereupon it could then be discharged onto the surrounding fields to be further filtered before working its way into the watercourse.

As with any construction project nowadays, reducing the project’s carbon footprint to a minimum was a high priority. The repair and refurbishment of existing structures is in itself a carbon saving measure, and significant CO2e savings were made through the sustainable approach of restoring the existing structure, as opposed to constructing a new bridge.

Other carbon saving measures were the implementation of effective waste management procedures. All timber, concrete and packaging waste, which totalled 98.99% of all the site waste, was diverted from landfill (thus saving 121 tonne of CO2e in the process). The use of HVO (Hydrotreated Vegetable Oil) fuel to power construction plant machinery, and utilising Eco Welfare Cabins on site further contributed to significant carbon savings.

The project team actively engaged with the local communities supporting various initiatives, as well as hosting a site tour for 30 engineering students from Liverpool John Moores University (which led to a six-week placement opportunity for one of the students as a Student Engineer with CRL). National Highways and CRL also partnered with the Environment Agency, the local fishing club and the Friends of the Dane Meadow volunteer group to manage the upkeep of the Dane Meadow nature reserve.

Jose Castro, Project Manager at CRL said: “We are very proud to have been involved in the award-winning refurbishment of this 60-year old concrete structure. This was a challenging project carried out over water and on a ‘live’ bridge. Early Contractor Involvement (ECI) was key to its success. Through the use of innovative engineering solutions and by undertaking the repair works in a carefully planned and executed manner, CRL has been able to deliver both cost and programme savings for the successful delivery of this scheme on behalf of National Highways."

“Not only did the refurbishment of the structure significantly reduce the carbon that would have been produced in comparison to the reconstruction of a new bridge, it also eliminated any major disruption to the travelling public using this route,” he added.

The River Dane Bridge project showcases CRL's commitment to innovation, sustainability, and collaboration. Through expert planning and execution, CRL delivered an award-winning refurbishment that ensured safety, reduced carbon impact, minimized disruption, and extended the bridge's lifespan for future generations.

"The team’s unwavering dedication to undertaking works safely and the quality of the repairs was nothing short of outstanding. Road safety was also always at the forefront of their role, but they also ensured that local communities were actively involved, every step of the way.”

Mangat Bansal| Programme Delivery Manager| National Highways